The egg tray making machine is an ingenious piece of equipment made for the production of high-quality egg trays, which are essential for packaging and moving eggs securely. Egg tray making devices cater to this demand by using an automated approach for creating trays that are not just resilient and lightweight however also ecologically pleasant.

The egg tray making procedure begins with the collection of waste or cardboard, which is after that shredded and incorporated with water to create a pulp. This pulp is an environmentally friendly choice to standard plastic egg trays, which posture significant disposal obstacles and add to ecological pollution. The pulp undertakes a refining process, ensuring that it attains the best uniformity for molding. Once prepared, the pulp is fed right into the egg tray making machine, where it is formed into trays utilizing mold and mildews that can fit different egg dimensions. The computerized nature of this equipment guarantees that manufacturing is both constant and effective, making it excellent for organizations seeking to scale their procedures.

One of the primary advantages of investing in an egg tray making machine is the substantial cost financial savings it uses. Conventional egg product packaging techniques commonly include sourcing and purchasing pre-made plastic trays, which can be expensive and subject to market variations.

The convenience of egg tray devices is another significant benefit. These machines can be set up to create different types of trays, including those for poultry eggs, quail eggs, and also fruit, depending on the mold and mildews utilized.

Safety is additionally a significant consideration in the egg sector, as eggs are fragile products prone to harm during transportation and handling. Well-designed egg trays supply the essential security, supporting the eggs and minimizing the threat of damage. This important capability is attained thanks to the special design of the trays, which features details depressions to safely hold each egg in location. This style not only decreases the possibility of physical damage to the eggs however also maximizes storage and shelving, making best use of room throughout distribution and retail procedures.

In addition to the physical advantages of utilizing egg trays, there are likewise significant marketing advantages. Eco-conscious consumers increasingly seek items that line up with their values, and biodegradable packaging is a substantial selling point. By utilizing an egg tray making machine to produce environmentally friendly trays, companies can efficiently market their products as sustainable and responsible options, maximizing a trend that shows no signs of decreasing.

The egg tray making machine runs effectively, commonly needing just a little team to supervise the production procedure. This performance brings about decrease labor expenses, and the machine's automated features reduce human mistake, making certain high-grade result with very little downtime. Modern equipments come geared up with innovative modern technology, including PLC (Programmable Logic Controller) systems, which provide customers real-time monitoring of manufacturing metrics, therefore boosting functional efficiency. This sophisticated remedy not just simplifies the manufacturing process yet likewise significantly minimizes the demand for manual work, developing more chances for firms to spend in their workforce in various other areas.

One more vital aspect adding to the popularity of egg tray devices is the capacity for personalization. Lots of producers supply a variety of options that permit organizations to customize their assembly line to fit their specific read more needs. This customization can include modifications in production ability, rate, and even the thickness of the trays produced. This degree of versatility indicates companies can adapt to market needs a lot more dynamically, scaling up or down based on changing conditions.

The international demand for eggs continues to increase, driven by an increase in intake in arising markets and altering nutritional preferences worldwide. Investing in an egg tray making machine currently allows services to place themselves advantageously in this developing market.

Some manufacturers have actually also integrated energy-efficient devices into their egg tray devices, better improving their sustainability allure. These machines can run with minimal energy usage, properly reducing the carbon footprint associated with egg tray production. This is particularly appealing to companies that are aiming to satisfy regulative demands or aiming to achieve sustainability certifications. It leads the means for them to market themselves as industry leaders in eco-friendliness, reeling in clients who prioritize these worths.

As several business owners and companies seek to expand their procedures, venturing into egg tray manufacturing uses a financially rewarding opportunity. The financial investment in an egg tray making machine is sustained by the premise of tapping right into a market with steady need. Provided the low first raw product costs and high return on financial investment, both new start-ups and well established companies can utilize on this opportunity. Entering this field lines up with more comprehensive trends towards lasting business procedures, where firms are held liable not only for their earnings but likewise for their social and ecological effect.

Establishing up an egg tray making machine calls for careful planning and consideration. By choosing to spend in a machine that offers high efficiency and modification, organizations stand far better opportunities of success in the competitive landscape of egg product packaging.

Past manufacturing, ongoing upkeep and assistance are vital components of operating an egg tray making machine. Numerous suppliers bieten comprehensive client solution and technological assistance, assisting businesses in fixing potential challenges and maximizing machine uptime.

Future innovations in egg tray making technology should also be taken into consideration when examining possible investments. Technologies in machine style, such as automated stacking systems, are most likely to emerge, further enhancing manufacturing effectiveness. Expecting these trends can permit organizations to stay ahead of the contour, making certain that they continue to be affordable in their offerings. Maintaining an eye on emerging technologies, materials, and manufacturing methods will certainly empower firms to grow and adapt in an ever-evolving market.

In conclusion, the egg tray making machine is a keystone of modern-day egg product packaging solutions, supplying considerable advantages in terms of efficiency, expense, and sustainability. As organizations look to optimize their procedures and meet the raising customer demand for environment-friendly items, this sophisticated machinery acts as an important property. By converting waste materials into functional, eco-friendly egg trays, firms can align their manufacturing processes with current worldwide fads and consumer actions. Eventually, the combination of an egg tray making machine stands for a calculated investment for businesses intending to operate sensibly while making sure profitability in the affordable world of egg production and product packaging. As demands advance and the value of sustainability proceeds to rise, engaging with this innovation comes to be not just a business decision, but a commitment to promoting a healthier world and an extra liable future for the industry.

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Phoebe Cates Then & Now!

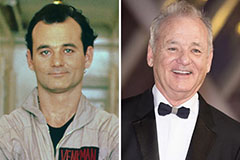

Phoebe Cates Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!